Quality Assurance Practices

- Start-up studies with FAI application,

- CoC regulations on a piece or batch basis,

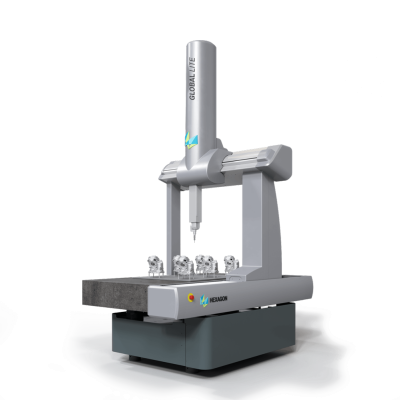

As efficiency is a crucial factor driving production, it is essential for the measurement process to provide the necessary data for application and seamlessly align with production workflows and cycle times. The GLOBAL S Coordinate Measuring Machine (CMM) delivers superior measurement performance and enhanced efficiency to meet specific production needs.

Typical applications include:

Additionally, the device is equipped with a rotating plate that can hold 3 lenses. As a result, when the workpiece requirement exceeds the magnification of one lens, the user can simply rotate the plate without changing another lens, making operation more convenient.

The focus adjustment can be done by moving the projection tube up and down. The non-rising or falling working table enhances the stability, measurement range, and accuracy of the device.”

A tailor-made and expandable ERP system is available that includes the following capabilities for traceability and efficiency.