5 Axis Vertical Machining Machine

Your powerful and flexible 5-sided machining solution for greater efficiency and productivity!

Max. X-Axis: 500mm

Max. Y-Axis: 450 mm

Max. Z-Axis: 400mm

Max. workpiece diameter: 630 mm

Max. workpiece height: 550 mm

Max. workpiece weight: 200 kg

Patented rotary table with excellent accessibility – your guaranteed advantage for complex production

B-axis rotation range from -5° to 110°

Complete machining of complex parts thanks to 5-axis technology

Wide table ø 630 x 500 mm for machining parts weighing up to 200 kg

3 Axis Vertical Machining Machine

YCM – EV1020A TECHNICAL SPECIFICATIONS

Maximum Spindle Speed 45 – 10,000 rpm.

Spindle Taper BT40

FRONT Bearing Diameter Ø 70 mm

MOVEMENTS :

X-Axis 1020 mm

Y Axis 520 mm

Z Axis 540 mm

The distance from the spindle center to the top surface of the table is 140 ~ 680 mm

Distance from spindle center to Z Axis guard 535 mm

TABLE :

Table Dimensions 1120 x 520 mm

T Channel (Number × Width × Step) 5 x 18 mm x 100 mm

Maximum Table Load 500 Kg

Maximum Spindle Speed 45 – 10,000 rpm.

Spindle Taper BT40

FRONT Bearing Diameter Ø 70 mm

MOVEMENTS :

X-Axis 1020 mm

Y Axis 520 mm

Z Axis 540 mm

The distance from the spindle center to the top surface of the table is 140 ~ 680 mm

Distance from spindle center to Z Axis guard 535 mm

TABLE :

Table Dimensions 1120 x 520 mm

T Channel (Number × Width × Step) 5 x 18 mm x 100 mm

Maximum Table Load 500 Kg

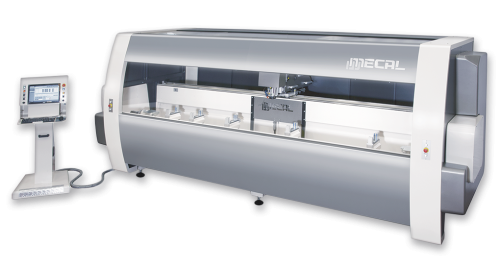

4 Axis Profile Machining Machine

Aluminum bar processing center

CNC controlled 4 axes (X, Y, Z, A)

For processing aluminium, steel, PVC and light metals

The beam of the vices can be located parallel to the longitudinal axis at all angles within ± 125 °.

Machinable cross-section: 300 x 150 mm (HxZ)

5 bad habits

Axis speed up to 150 m/min

This machine processes bars up to 4000mm useful length and using differentiated working cycle the machine can then process bars up to 8000mm.

CNC controlled 4 axes (X, Y, Z, A)

For processing aluminium, steel, PVC and light metals

The beam of the vices can be located parallel to the longitudinal axis at all angles within ± 125 °.

Machinable cross-section: 300 x 150 mm (HxZ)

5 bad habits

Axis speed up to 150 m/min

This machine processes bars up to 4000mm useful length and using differentiated working cycle the machine can then process bars up to 8000mm.

Our C Axis Lathe

Body Type: 45°

Maximum Turning Diameter:650 mm

Max Machining Diameter:405 mm

Maximum Machining Length: 1,020 mm

Spindle Diameter: 68 mm

Spindle Speed: 4.500 rpm

Spindle Motor: 15/18.5 kW

Mirror Size: 8 inches

Axis Speeds ( X/Z ):24/30 m/min

Number of Turret Items: 12 (BMT65)

Pen Dimensions: 25×25 mm

Hole Pen Size: 50 mm

Tailstock Movement: 110 mm

C Axis Speed:5.000 rpm

Maximum Turning Diameter:650 mm

Max Machining Diameter:405 mm

Maximum Machining Length: 1,020 mm

Spindle Diameter: 68 mm

Spindle Speed: 4.500 rpm

Spindle Motor: 15/18.5 kW

Mirror Size: 8 inches

Axis Speeds ( X/Z ):24/30 m/min

Number of Turret Items: 12 (BMT65)

Pen Dimensions: 25×25 mm

Hole Pen Size: 50 mm

Tailstock Movement: 110 mm

C Axis Speed:5.000 rpm

Our 5 Axis Twisting Machine

6 Axis Servo Controlled

Maximum Pipe Diameter: Ø32

Maximum Wall Thickness: 2,5mm

Maximum Bend Radius: 150 mm

Ability to Bend with 3 Different Radius on the Same Pipe

Rolling Feature

Hole Drilling Feature

3D Simulation

3D Drawing Reading Feature

Pipe Collision Stimulating Simulation Program

3D Preview Feature of the Pipe to be Bend

Technical Drawings Drawn with AutoCAD or Solidworks Program (.step, .igs Extension) Ability to Transfer and Bend to the Control Panel of the Machine via Internet and USB

Maximum Pipe Diameter: Ø32

Maximum Wall Thickness: 2,5mm

Maximum Bend Radius: 150 mm

Ability to Bend with 3 Different Radius on the Same Pipe

Rolling Feature

Hole Drilling Feature

3D Simulation

3D Drawing Reading Feature

Pipe Collision Stimulating Simulation Program

3D Preview Feature of the Pipe to be Bend

Technical Drawings Drawn with AutoCAD or Solidworks Program (.step, .igs Extension) Ability to Transfer and Bend to the Control Panel of the Machine via Internet and USB

C Type Mechanıcal Press - 120 Tonnes

Tonne:120

Stroke Adjustment (mm): 20-120

Speed (d/dk): 50

Bed Area (mm):650×925

Distance Bed Tostide (mm):470

Hole In Slide (mm):55

Hole In Bed (mm):200-220

Weight (kg): 5200

Motor Power (hp):10

Size x – z – y (mm): 1900-2000-2450

Stroke Adjustment (mm): 20-120

Speed (d/dk): 50

Bed Area (mm):650×925

Distance Bed Tostide (mm):470

Hole In Slide (mm):55

Hole In Bed (mm):200-220

Weight (kg): 5200

Motor Power (hp):10

Size x – z – y (mm): 1900-2000-2450

V350-HX Circle Saw

Semi-automatic sawing machine that makes material clamping and cutting automatically,

Double transmission helical gear system

Complete casting table

Adjustable and controllable cutting speed thanks to the hydro-pneumatic working saw head,

Ability to select the most suitable speed for material properties thanks to the double-speed motor

Precise angle cuts up to 45⁰ in both directions

Stroke adjustment to the cutting start and end points according to the size of the material to be cut

Thanks to the coolant tank and engine in the cabinet, the saw can be cooled and quickly removed from the cutting surface.

The pieces can be cut to the same length as standard after being adjusted once with the special support mechanism.

Security system in accordance with CE Norms

Double transmission helical gear system

Complete casting table

Adjustable and controllable cutting speed thanks to the hydro-pneumatic working saw head,

Ability to select the most suitable speed for material properties thanks to the double-speed motor

Precise angle cuts up to 45⁰ in both directions

Stroke adjustment to the cutting start and end points according to the size of the material to be cut

Thanks to the coolant tank and engine in the cabinet, the saw can be cooled and quickly removed from the cutting surface.

The pieces can be cut to the same length as standard after being adjusted once with the special support mechanism.

Security system in accordance with CE Norms

Motoman AR2010

MOTOMAN AR2010 is perfect for robotic arc welding, cutting and other path-related applications. It combines precision, performance and functionality in a way which made MOTOMAN welding robots superior over the last decades. The AR2010 allows you to achieve optimal welding results even under extremely difficult conditions.

Number of axes: 6

Repeatability: 0.03 mm

S-axis: 210°/s

L-axis: 210°/s

U-axis: 220°/s

R axis: 435°/s

B-axis: 435°/s

T axis: 700°/s

Kaban AC 1050 Aluminium Cutting Machine

Precise cutting of Aluminium profiles between 200-1350.

Has lubrication system.

Left feeding table and automatic saw safety cover.

Profile support arm between two heads.

Special vacuum system to cut without depositing sawdust on heads.

Profile height measuring system.

Automatic slicing system.

Has lubrication system.

Left feeding table and automatic saw safety cover.

Profile support arm between two heads.

Special vacuum system to cut without depositing sawdust on heads.

Profile height measuring system.

Automatic slicing system.